Jun. 09, 2021

Tips For Improving Conveyor Belt Efficiency And Preventing Downtime

Perhaps more than any other manufacturing and inventory management equipment, conveyor belt systems have the potential to make workers safer and more productive. When the design and operation are effective, the conveyor belt streamlines movement, finished products, components, packaging, and more. However, conveyor belt failures may throw production workshops and warehouses into chaos; hinder workflow, accumulate materials, destroy valuable inventory, and may endanger workers.

All organizations strive to maintain normal production and create a safe working environment. Ensuring the best conveyor belt efficiency goes a long way to achieving these goals. Stagnant conveyor belt systems are costly and stressful, so keeping them running at all costs is critical.

Tips for pre-production belt selection

Even before your plant is put into operation, considering various factors can positively affect your conveying efficiency.

Considering the load your conveyor belt handles-the size, weight, dimensions, and other characteristics of the load, your conveyor belt will be transporting will help determine the materials, motors, drives, and hardware that are suitable for your application. Other product aspects such as temperature and materials will also affect the choice. First, understand the difference between traditional belts and plastic modular belts. In general, it is a good idea to review design options with belt experts to consider all the different belt options.

Set your conveyor belting to pull instead of push-pulling is more effective than pushing. Your conveyor belt will lose 50-70% of its load capacity when pushing.

Consider the flow rate-how fast and precise you need material to be transported or removed from the conveyor may require specific equipment. For example, in the distribution and airport industries, fast-moving conveyor belts are essential. For fast-moving conveyor belts, you may need fasteners, endless splicing equipment, segmented transfer plates, and maintenance tools.

Understand the requirements of your industry-if you will be transporting food and beverage products or pharmaceutical ingredients, you must consider material density, as well as hygiene factors.

Prompt for conveyor belt selection during production

Taking the time to inspect your conveyor belts and perform preventive maintenance can save money in the long run, and can prevent major failures from damaging the product, putting employees in danger, or causing downtime.

Routine inspection-In accordance with the conveyor belt manufacturer's recommendations, the bearings, pulleys, and other components are inspected daily, weekly, monthly and quarterly. Insist that your maintenance team, whether internal or external, record every inspection and preventive measure taken.

Keep it clean-although this is important for food, dairy, cosmetics, and pharmaceutical companies, conveyor belts in all industries will be more efficient through regular cleaning and lubrication. The cleaning solution will reduce energy use, as well as friction and slippage, which will exhaust the life of motors, rollers, and other moving parts. Depending on your business, it may be worthwhile to invest in a clean-in-place system.

Replace parts before they break down-predictive maintenance can not only help you avoid catastrophic failures, but also maintain productivity. The bad part is more likely to be broken, resulting in production constraints. But they are also often responsible for unsatisfactory work processes, which erode revenue and profits. For predictive and preventive maintenance, we recommend keeping key components at hand or at least having a conveyor belt supplier in your corner that can get you back up and running quickly.

Safety, training, and logistics tips

Conveyor belt systems are an indispensable participant in many productions, distribution, and supply chain environments. However, for conveyor belts to reach their full productivity potential, organizations must ensure that they are placed and used correctly.

Inspection and calibration-When setting up the conveyor belt for the first time, the inspector should ensure that all safety mechanisms-pull stops, machine guards, enclosures, railings, warning labels, etc.-are in place and secure. Conveyors should be calibrated and adjusted to ensure that they are still easy for workers to use and meet standards. Vibration, contact with people or carts, and other daily working conditions can cause the belt to deviate from a straight line or otherwise reduce its value.

Design a safe and efficient workstation-if your conveyor belt is part of the workstation where the staff picks, packs, assembles, or inspects items, then ergonomics must be considered. Design workstations to help employees increase productivity and reduce the risk of harming themselves. The less time they spend on bending, stretching, and twisting, the better their performance. Design the height of the conveyor belt to fit your tallest operator. A platform should also be provided so that shorter employees can work comfortably there. Make sure the items they need are easily accessible.

Cultivate a safety culture-Encourage your employees to report their safety concerns and make suggestions to make their conveyor belt work easier or more efficient. A zero-tolerance policy for misuse of conveyor belts is adopted to ensure that every employee knows how to stop the conveyor belt in an emergency.

The efficiency and longevity of the conveyor belt can only be achieved through proper planning and maintenance. Pre-production planning and regular maintenance may seem inconvenient, but in the long run, they will ultimately help prevent pauses and downtime in the production process, which will translate into higher profits and less wasted time.

We are conveyor belt manufacturers. Please feel free to contact us if you are interested in our products.

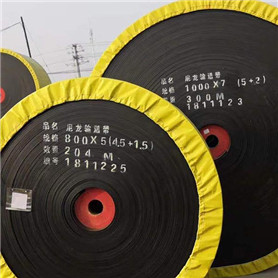

conveyor belt