Apr. 29, 2019

The wide application of the conveyor greatly improves the working efficiency. It can reach the quantity of materials within the specified time. Before using the application, the application checks the components, whether the tape buckle and the carrying device are normal.

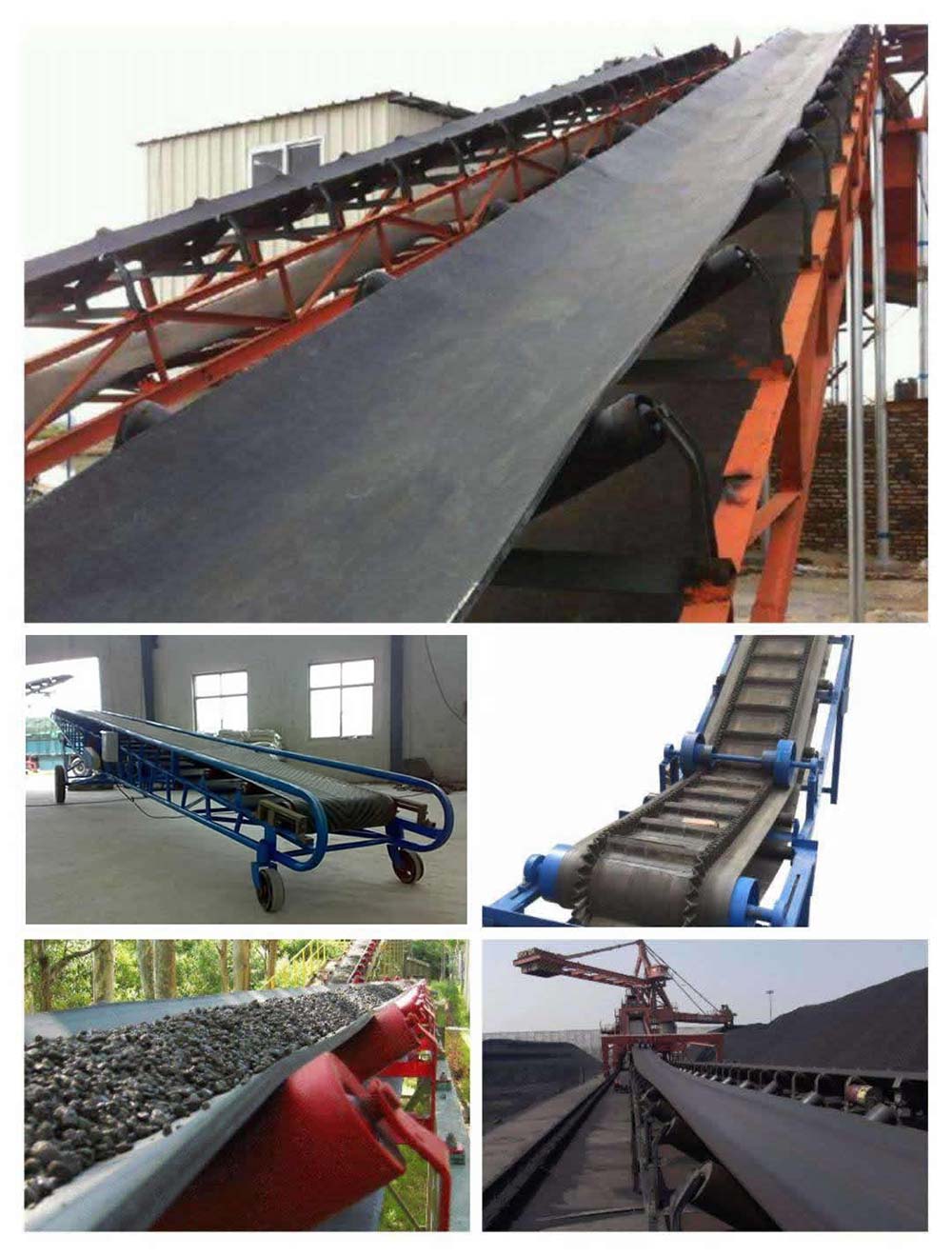

The conveyor is impacted by materials, ore, coal or even metal for a long time, posing conflict and severe impact wear. The most common impact is the impact wear of the drum and the impact wear of the guide. Some materials are relatively fine, and they are also due to the production process and equipment viewpoint, material humidity and other reasons, which constitute the accumulation of materials. Conveyors should generally be launched under no-load conditions.

When multiple belt conveyors are used in sequence, the equipment that can be blocked should be used to start and stop by the gathering control room. In addition, in order to prevent the occurrence of the incident, each conveyor should also be set up on the site to initiate or connect buttons, you can park at any time.

In order to prevent the conveyor belt from being longitudinally torn for some reason, when the length of the conveyor belt exceeds 30 meters, a continuous button should be placed along the full length of the conveyor belt at a certain distance (for example, 25 meters).

In the equipment transmission equipment, it is necessary to pay attention to make the belt of the belt conveyor perpendicular to the center line of the belt conveyor, so that the center of the transmission drum coincides with the center line of the conveyor belt, so that the shaft of the speed reducer is parallel to the transmission shaft. Together, all shafts and rolls should be flat.