Mar. 27, 2020

5. Oil resistant conveyor belt

Oil-resistant conveyor belt covering rubber uses high-acrylonitrile-based nitrile rubber as the main material, and cotton canvas, nylon canvas, or EP canvas is used as the strong layer. Suitable for transporting oily materials and in contact with various working oils (except fuel oil or solvent oil). It has the advantages of low volume change rate, high strength retention rate, and wide application range.

Oil Resistant Conveyor Belt

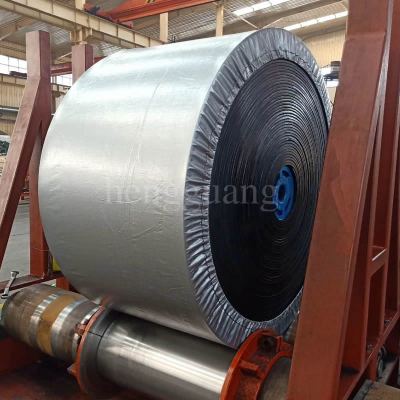

6. polyester (EP) conveyor belt

The polyester conveyor belt is made of multilayer polyester (or polyester in the warp direction and polyester amine in weft direction) bonded together in a certain way. The upper and lower covers are high-strength and elastic rubber. It is used for conveying small and medium block / granular / powder materials. Suitable for medium and long-distance, high load, high speed conveying materials.

Variety: According to the performance of the covering rubber, it can be divided into strong scratch type / strong wear type / general type/acid and alkali resistant / flame resistant type for general use. In addition to the many advantages of nylon conveyor belts, EP conveyor belts have length The small, wet strength does not reduce the unique advantages. This is especially important for long-distance transport and wet working conditions.

7. the whole core flame-retardant conveyor belt

The whole core flame-retardant conveyor belt is made of the entire belt core after being impregnated with plasticized or vulcanized polyvinyl chloride impregnated paste. It has the characteristics of high strength, large capacity, and balanced transportation. At the same time, the product has good flame retardant and antistatic properties. , Impact resistance, wear resistance, corrosion resistance, and other properties. This product is mainly suitable for underground transportation of coal mines, and can also be used for material transportation in metallurgical and chemical industries.

The mining conveyor belt can be divided into PVC type and PVG type.

The upper and lower covering layers of PVC are PVC cover rubber, single-sided adhesive ≥0.8mm, the upper and lower covering layers of PVG are both nitrile rubber and PVC, and the thickness of one side is 1.5mm-4.5mm. The inclination angle of the PVC conveyor belt is <16o, and the inclination angle of the PVG conveyor belt is <20o, which can be used for coal mine underground and underground transportation.

The belt features: the belt body does not delaminate, the elongation is small, impact resistance, tear resistance. According to different knots, it can be divided into PVC type (plastic surface), PVG type (with rubber surface on the basis of PVC), and the whole core flame-retardant tape, which implements the MT / 914-2002 standard. ○ PVC type is suitable for conveying materials under dry conditions with an inclination angle below 16 degrees. ○ PVG type is suitable for the transportation of moist watery materials with an inclination angle below 20 degrees 2. Flame retardant performance: (1) Roller grinding number: The surface temperature of the roller is not greater than 325 ° C. (2) Burning of the torch: The flame-free time of the torch of the full-thickness specimen is not more than 3.0S on average, and the average of removing the cover is not more than 5.0S.