Apr. 03, 2020

The role of the roller is to support the conveyor belt and the weight of the material. The idler operation must be flexible and reliable. Reducing the friction between the conveyor belt and the supporting rollers plays a key role in the life of the conveyor belt which accounts for more than 25% of the total cost of the conveyor. Although the idler is a smaller part in the china belt conveyor machine and the structure is not complicated, it is not easy to make a high-quality idler.

There are several criteria for judging the quality of the idler: the radial runout of the idler; the flexibility of the idler; and the axial shift.

Main classification:

1. Divided into rubber roller, ceramic roller, nylon roller and insulation roller according to material.

2. There are mainly grooved idler roller groups, various types of parallel idler roller groups, various self-aligning idler roller groups, and various buffer idler roller groups.

(1) Slotted rollers include common type rollers, forward type rollers, quick-change bearing rollers, hanging type rollers, triple chain rollers, reversible rollers, variable groove angle rollers, transitional rollers Rollers, V-shaped rollers, etc .;

(2) Parallel idlers include ordinary idlers, comb idlers, forward inclined idlers, steel rubber idlers, spiral idlers, etc .;

(3) Self-aligning idlers include general purpose, friction reversible idlers, powerful idlers, tapered idlers, spiral idlers, combined idlers, etc .;

(4) Buffer rollers include spring plate rollers, buffer ring rollers, strong buffer rollers, adjustable elastic rollers, hanging rollers, etc .;

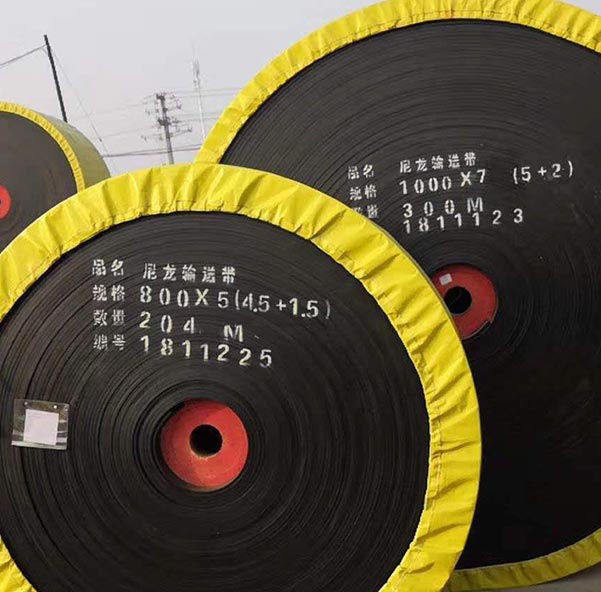

Nylon Roller

Ceramic roller

Ceramic rollers are simply referred to as ceramic rollers. This product not only has the characteristics of wear resistance, acid and alkali resistance, oxidation resistance, stable operation, anti-theft, etc., but ceramic rollers can effectively prevent the belt from running away, reduce local loss of the belt, and extend the use of the belt. Service life reduces the frequent replacement of rollers for use in harsh outdoor environments. Ceramic rollers have a much longer life than ordinary rollers. Ceramic rollers have high strength and good wear resistance. Ceramic rollers have a long service life and can reduce belt wear. High temperature resistance, oxidation resistance, strong corrosion resistance, ceramic rollers are suitable for various harsh environments. No static electricity, sparks are not easy to occur during abrasion and collision, and ceramic idlers are suitable for easy environments such as coal mines. Stable performance, can effectively prevent the belt conveyor from drifting, pulling forks and generating heat.

Nylon idler: low friction coefficient, abrasion resistance, not easy to damage the belt. It has excellent self-lubricity, and can be used under harsh environmental conditions without oiling during use. It is not easy to jam and has good anti-magnetic properties. Corrosion resistance, strong aging resistance, resistance to weak acids, weak alkalis and organic solvents, non-toxic and non-polluting, can withstand repeated shocks and vibrations. The nylon roller itself is light weight, only one third of the metal parts, easy to install, low maintenance rate, low noise, stable operation, energy saving, can improve the service life of the nylon roller, dustproof, good waterproof performance, in the environment of multiple ash It is not easy to get water in use. Nylon roller supplier produces nylon rollers with complete specifications and models, which can produce diameter, length, and special specifications can be customized as required.

Features of nylon idler:

1. Nylon idler roller has extremely high abrasion resistance, extremely low friction coefficient, and it is not easy to wear the belt;

2. Nylon idler has excellent self-lubrication, no oil is needed, and it is not easy to be stuck under severe conditions;

3. The nylon roller has antistatic, antismoldering, aging resistance, and chemical (acid, alkali and organic solvent) corrosion resistance;

4, can withstand repeated shocks and vibrations;

5. The working temperature range of nylon roller is: -40 ℃ ~ 80 ℃;

6, excellent mechanical properties, light weight, easy installation, no maintenance required;

7. Nylon idler with low noise (3-7DB) runs smoothly and has a long life (3-5 times the life of metal idler)