Mar. 23, 2020

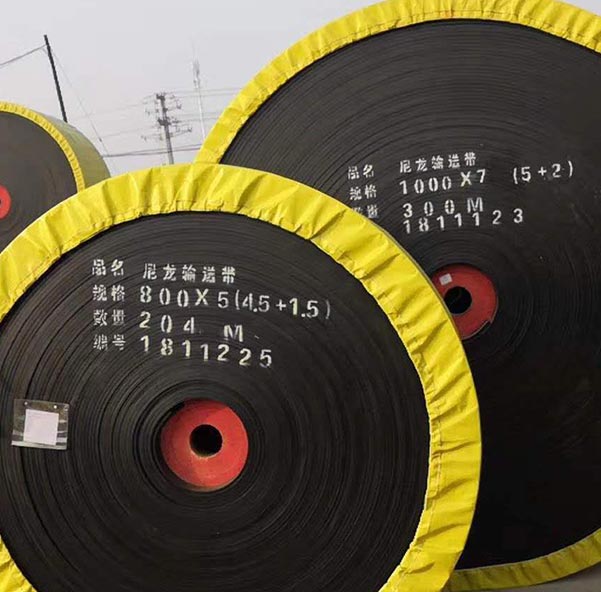

First, Nylon conveyor belt

Nylon conveyor belt is a multi-layer nylon canvas bonded together in a certain way, covering up and down with strong and elastic wear-resistant rubber. It is used to transport medium and small block / granular / powder objects, suitable for high-speed, medium-long distance and large impact-resistant transportation.

Variety: According to the performance of the covering rubber, it can be divided into general use type and wear-resistant / flammable type. Nylon core conveyor belt has the characteristics of thin belt, high strength, high impact resistance, good performance, large interlayer adhesion strength, excellent flexibility, different life, longevity, long life, etc., suitable for medium and long distances, high Load material at high speed.

Compared with ordinary cotton core conveyor belts, nylon conveyor belts have the advantages of high strength, good elasticity, impact resistance, light weight, and good groove formation. It can effectively reduce transportation costs and achieve high-speed, long-span, and long-distance transportation.

Nylon Conveyor Belt

2. Cotton canvas conveyor belt

1. Refined from cotton canvas (CC) or virgin cotton interweave canvas (VC) after calendering, forming, and vulcanizing.

2. This product is suitable for conveying non-corrosive non-spike-like massive, granular and powdery materials such as coal, coke, sand, cement and other bulk materials (materials) or pieces at room temperature.

Three acid and alkali resistant conveyor belt

In the working environment in contact with acids and bases, such as phosphate fertilizer manufacturing, seawater sun salt, and covering rubber, rubber and plastic are blended and filled with inert materials with excellent acid and alkali resistance, which are better than chloroprene rubber acid and alkali resistant conveyor belts. The skeleton material uses EP canvas, which is more resistant to acid and alkali than cotton canvas core belt. Generally made into a ring.

Polyester (EP) conveyor belt, polyester conveyor belt is composed of multi-layer polyester (or warp polyester, weft is polyester amine) canvas together in a certain way, the upper and lower covering rubber is strong, good elasticity Of wear-resistant rubber.

It is used for conveying small and medium block / granular / powder materials. Suitable for medium and long distance, high load, high speed conveying materials.

Variety: According to the performance of the covering rubber, it can be divided into strong scratch type / strong wear type / general type / acid and alkali resistant / flame resistant type for general use. In addition to the many advantages of nylon conveyor belts, EP conveyor belts also have length The small, wet state strength does not decrease at all. This is especially important for long-distance transport and wet working conditions.

4. Heat-resistant conveyor belt

The heat-resistant conveyor belt is mainly used for conveying high-temperature materials, such as sintered ore, hot coke, cement clinker, and hot casting. According to the main manifestation of the heat-resistant belt being broken or even losing the conveying ability and different heat-resistant grades, EPDM or styrene-butadiene rubber is used as the covering rubber; high-strength and high-penetration polyester canvas or cotton canvas is used as the strength layer. A heat-resistant glass cloth can be supplemented between the covering rubber and the framework layer to improve the service life of the heat-resistant belt. According to user requirements, it can be made into ring belt.